Oyster Shell Contains 92 % of calcium carbonate.

Based on its mineral properties, oyster shell is a suitable alternative to replace limestone in cement manufacturing as one of the raw materials.

Oyster Shell Contains 92 % of calcium carbonate.

Based on its mineral properties, oyster shell is a suitable alternative to replace limestone in cement manufacturing as one of the raw materials.

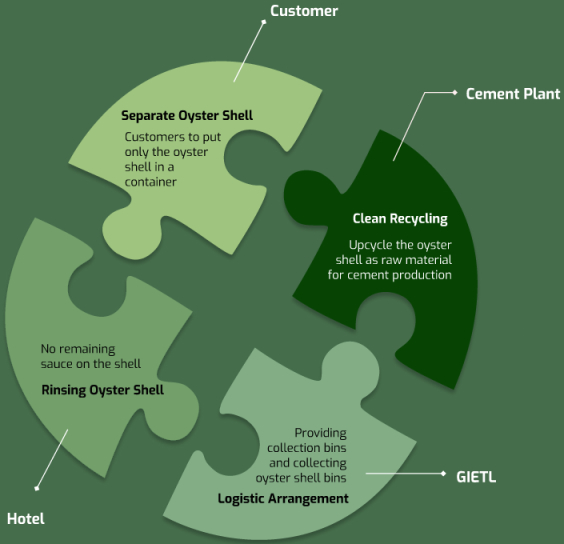

ShellCem Project employs an "All People Engagement" approach to enhance the recycling process. This means not only one party or organization is responsible for waste handing, but also all communities and individuals who contribute for the waste generation and circular economy.

Launching a kick-off meeting to compromise a washing process which effectively aligns with the operations of the hotel side and cement manufacturing.

Based on the oyster shell quantity generated from the hotel side, GIETL and the hotel would work out a regular schedule in oyster shell collection.

Based on the agreed schedule, GIETL would arrange for logistic collection to assigned location.

After the collection, the oyster shell would be weighed by GIETL. A monthly report of oyster shell collected would then be provided to the hotel monthly.